Whether producing a field crop or tomatoes, there are perhaps as many recipes for ideal tomato production in hydroponics systems. There are many different media being utilized as growing medium and each medium requires its own program for optimal crop production.

There is no ideal generalized program that could be used as a ubiquitous nutrient solution for production of tomatoes in many different areas and under many different conditions.

Factors Influencing Hydroponic Tomato Production

There are many factors that can affect the composition of the nutrient solution for optimal production of tomatoes in hydroponics. Firstly, the environment, primarily temperatures and humidity, water quality, nutrient composition of the water, growing medium, season and type of tomato being produced.

The designing of any nutrient solution should begin with the quality of water to be used. A complete water analysis should be conducted on a regular basis to ascertain what nutrients can be found in the water. If managed correctly, a large proportion of these nutrients can be incorporated into the nutrient solution, thereby reducing the required number of fertilizers to achieve the specified nutrient solution.

Temperature, humidity and season, all affect the movement of water through the plants and consequently the uptake of nutrients by the plant. Although not all nutrients are taken up through the transpiration stream, some essential nutrients are.

The Role of Water Quality and Growing Media

Growing media react differently to the nutrient solution, whether shavings or coir, rockwool or sand. There are many different types of media available to the farmer. Even the bags or troughs used will affect the final nutrient composition for your crop.

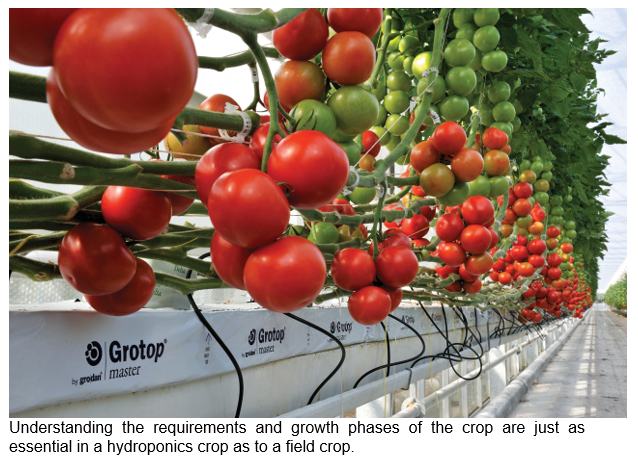

Then there is the tomato crop itself. Not just whether producing a saladette, salad, cherry or pink tomatoes, but also the phase of growth of the tomato crop. Understanding the requirements and growth phases of the crop are just as essential in a hydroponics crop as to a field crop. Often however, there are limitations within a system preventing the use of two different nutrient solutions on different phases at the same time.

Available standard “complete” mix products are designed to be an easy-to-use mix of nutrients. A standard recipe is usually provided requiring a specific mix of up to 3 products to achieve a certain nutrient regime in the solution. These mixes are used often more for convenience than for achieving an ideal solution for a crop.

The cost of these solutions is often generally higher than the “straight mixes” which are composed of up to 7 different products in varying amounts to achieve a specific nutrient regime.

Associated with all the “ideal” nutrient solutions and norms that are available to the tunnel tomato farmer, one can find just as many if not more nutrient ratios to design an ideal nutrient solution. N:K ratios varying from 1.8 to 2.2 depending on growth phase, Ca:Mg ratios of 3.5 – 4, Ca:K of between 1 – 2. These variations represent differences of up to 50% of the nutrient content in the solution.

Despite this, these ratios can be very helpful in providing the necessary suspected requirements of the crop within the area of production. Not all the ratios are right, and not all of these are wrong either. Each norm is perhaps developed under certain conditions and performed best under those conditions.

Then how does one achieve the ultimate nutrient solution? It is achievable but does take a lot of time and effort to establish. A good starting point would be the nutrient norms of one of the complete mixes mentioned above, mixed as individual products to create your solution, considering the nutrient composition of your water. Taking leaf analyses regularly during your crop will help to determine the nutrient composition of your crop at that point in time.

The nutrient solution can be adjusted based on the leaf analysis results, and perhaps even on the visual perception of the crop. It is not recommended to take leaf analyses more frequently than every month as it can take as much time for the plant to correct itself from the previous change. This is a slow process, but over time, it is possible to have an “ideal” solution for your location that is unique to your environment and conditions.

The Role of Electrical Conductivity (EC) in Tomato Production

There is much discussion in the industry as to the EC (Electrical Conductivity) that is optimum for tomato production. The EC is a measurement of all the salts and nutrients that may be found in the nutrient solution. It is unable to tell the user what is in the solution, just how much of everything is present.

There has been a lot of work done around the world looking at different EC’s and the effects on yield, quality and growth of tomato plants. There are many different theories available to the farmer as to starting EC, changing through to harvest and the end of the crop.

The EC’s chosen should be related to the variety being grown. Some varieties are more vigorous and prefer lower EC’s, whilst other varieties can tolerate higher EC’s. Knowing the requirements of the variety will help also with the ratios.

Starting at a low EC and gradually building up over the growth of the crop, according to growth phase, for example starting at EC of 1.5 mS/cm and ending at an EC of 2 to 2.2 mS/cm has many benefits to tomato production. Applying lower concentrations of nutrients at an earlier stage will supply the plant with more of what it requires at the young stage without imposing stress on the plant. This is a more controlled approach where only limited amounts of fertilizer reach the plant preventing it from becoming to vigorous, an undesirable attribute in tunnel production.

High EC Practices and Their Implications

There has been a recent trend in various parts of the country where high EC’s are used in the initial phases of growth, lowering to “normal” levels as above, for example, starting at an EC of 3 mS/cm and ending at 2.2 mS/cm. The idea behind this is to stress the young plant into flowering sooner. Inherent problems with this include the lasting impact of that stress on the young plant.

If not carefully managed, such high initial EC’s can cause serious damage to the young plant. Also, the effect of the high EC may not cause earlier flowering since often, the flowers are formed in the nursery before the plants reach the farm. If such a practice is found to bring about earlier flowering, does the increased cost of production by a minimum of 50% result in increased savings of at least 50%. A simple question – if it does not provide the returns, why increase your costs?

A study was conducted by the University of Stellenbosch to establish whether it was feasible to use higher EC’s in tomato production, particularly in achieving higher flavoured tomatoes. A 30% reduction in yield was found by increasing the EC from 2.2 to 3.9 mS/cm. This loss in yield was not attributed to reduced numbers of fruit, but more to reduced fruit size.

An interesting point to note was that taste was not improved at higher EC’s, however they did find the total soluble salts was increased (TSS, % Brix). Cultivar choice could be a more effective choice at improved flavour than increased EC.

Where chain stores are demanding improved flavour tomatoes, these studies did show that it can be achieved by higher EC’s or by cultivar choice. The problems facing the farmer would then include reduced yields combined with increased costs in production and the same returns in production.

Conclusion: Navigating the Complexities of Hydroponic Tomato Production

Just as with field production, hydroponics tomato production with regards to fertilization is becoming more important with increased care and attention being required to achieve the results being demanded. Critical management of costs of production are also just as important for a grower to remain competitive in such a tough market. From studies made by Prof Nic Combrink.